Flexible heating strips and films are used in electronics, 3D printing beds, tooling, and custom appliance repairs. Below is a quick comparison of five relevant flexible heater products chosen for versatility, voltage options, sizes, and application types.

| Product | Brand | Type / Key Spec |

|---|---|---|

| 6pcs 45mmx100mm Film Heater Plate Adhesive Pad | Coliao | Polyimide Film, 24V 30W, 45×100 mm |

| 10 PCS 45mmx100mm Film Heater Plate Adhesive Pad | DWEII | Polyimide Film, 24V 30W, 45×100 mm |

| 10 PCS 10mmx93mm Film Heater Plate Adhesive Pad | DWEII | Polyimide Film, 12V 12W, 10×93 mm |

| 11″ Wide 4 Feet Long Flex Watt Heat Tape | Flexwatt | Heat Tape, Continuous 11″×4 ft |

| 24″ Portable Acrylic Plastic PVC Bending Machine | Gdrasuya10 | Portable Bender With Built-In Heaters, 110V 800W |

Content Navigation

Coliao 45x100mm 24V Polyimide Film Heater

This polyimide film heater is a self-contained adhesive pad sized 45mm x 100mm rated at DC 24V and 30W. The product highlights include a maximum temperature near 170°C and a construction that uses polyimide for external insulation and thermo-foil as the internal heating element.

Key technical points: the heating film does not include an integrated thermostat, so external temperature control is required for regulated applications. The polyimide outer layer offers high thermal efficiency, heat resistance, and dielectric strength, suitable for localized surface heating, small tooling, or part warming.

Application notes: recommended for flat surfaces where a thin, conformal heat source is needed. Use with a compatible 24V controller, thermal sensor, and proper adhesion procedures to ensure consistent heat transfer and safe operation.

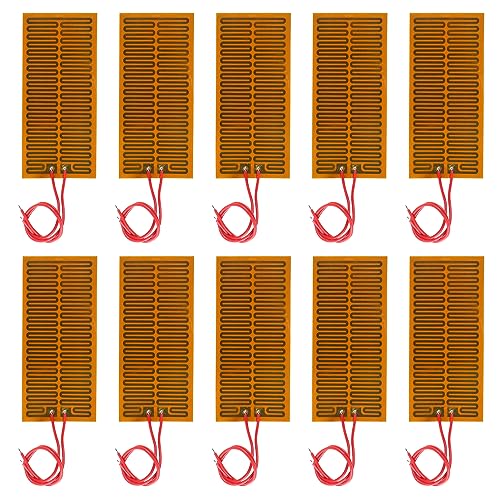

DWEII 45x100mm 24V PI Heater Pads

Call 888-896-7031 for Free Local HVAC Quotes – Compare and Save Today!

This DWEII pack contains ten polyimide film heater pads sized 45mm x 100mm, rated at 24V DC and 30W with a listed maximum temperature around 170°C. The construction emphasizes dielectric strength and thermal conductivity stability.

Like similar PI heaters, these pads are not self-regulating and are intended to be used with external temperature controls for safe, repeatable operation. The film format makes them useful for 3D printer bed upgrades, localized device heating, and process preheating where a thin profile and good thermal contact are important.

Installation considerations: ensure even adhesion and avoid creases or air gaps. When paired with a temperature controller and sensor, these pads can provide reliable, uniform heating for small surfaces and assemblies.

DWEII 10x93mm 12V Film Heater Strips

This set of ten 12V polyimide heater strips measures 10mm x 93mm and is rated at 12W per element with a maximum temperature near 150°C. The strips include adhesive backing for straightforward mounting on narrow surfaces or elongated components.

Use cases: the narrow strip geometry suits heating pipes, small housings, sensor mounts, or areas that require a linear heat source. These are useful where lower voltage operation is preferred or required by the surrounding electronics.

Call 888-896-7031 for Free Local HVAC Quotes – Compare and Save Today!

Safety and control: they share the same limitation of film heaters — no built-in temperature control. A 12V temperature controller and appropriate thermal sensor should be used to prevent overheating and to maintain consistent setpoints.

Flexwatt 11″ Wide Flex Watt Heat Tape

The Flexwatt product is an 11-inch-wide continuous heat tape available in a 4-foot length. This style of flexible heat tape (watt tape) delivers distributed heating across a wider surface area compared to narrow film strips.

Typical applications include pipe freeze protection, surface warming, curing, and flexible wrap-around heating for larger components. The continuous nature of the tape makes it practical for creating elongated heating zones with fewer seams.

Installation and control: heat tape may require secure fastening and an appropriate power source plus a controller or thermostat designed for watt tape use. Consider insulation over the tape to increase efficiency and protect the assembly.

Portable 24″ Acrylic PVC Heater Bender

This portable plastic bender integrates heating elements designed for hot bending acrylic and PVC sheet materials. It is rated for 110V input and 800W power, with the capability to heat simultaneously from top and bottom for even temperature distribution along the bending line.

Relevant for heater selection: the bender contains tubular heater elements and a built-in circulating water cooling system to limit thermal spread. While not a flexible heater strip in itself, it demonstrates an application where controlled, linear heating is used for forming plastics.

Usage notes: suitable for sign makers and workshops needing a controlled heating edge. Temperature adjustability and the option to combine multiple heaters for longer runs provide flexibility similar to modular heater strip designs.

Buying Guide: How To Choose A Flex Strip Heater

Selecting the right flexible heater requires matching electrical, thermal, and mechanical requirements to the heater form factor. The following considerations will help compare options objectively.

Tips for Getting the Best HVAC Prices

- Prioritize Quality Over Cost

The most critical factor in any HVAC project is the quality of the installation. Don’t compromise on contractor expertise just to save money. - Check for Rebates

Always research current rebates and incentives — they can significantly reduce your overall cost. - Compare Multiple Quotes

Request at least three estimates before making your choice. You can click here to get three free quotes from local professionals. These quotes include available rebates and tax credits and automatically exclude unqualified contractors. - Negotiate Smartly

Once you've chosen a contractor, use the proven strategies from our guide — How Homeowners Can Negotiate with HVAC Dealers — to get the best possible final price.

Voltage And Power Matching

- Voltage Compatibility: Choose heaters rated for your available control voltage (commonly 12V or 24V for polyimide films). Ensure compatibility with controllers and power supplies.

- Power Density: Watts per area determine heating speed and peak achievable temperature. Higher power density produces faster warm-up and higher surface temperatures, but requires careful control.

Temperature Range And Control

- Maximum Temperature: Match the heater’s max temp to the thermal tolerance of the target surface and any adhesives or components nearby.

- Control Needs: Most film heaters are not self-regulating. Plan for a temperature controller, appropriate sensors (thermocouple or thermistor), and safety cutoffs.

Form Factor And Flexibility

- Strip vs Tape vs Bender: Narrow strips and small pads suit localized spots. Wider watt tape covers broader areas. Integrated heater tools (benders) provide linear heating for forming processes.

- Adhesive Backing: Self-adhesive films simplify mounting; ensure the adhesive tolerates operating temperatures.

Thermal Contact And Installation

- Surface Preparation: Clean, flat surfaces maximize thermal transfer. Air gaps reduce efficiency and create hot spots.

- Insulation: Adding insulation over the heater improves efficiency and reduces energy consumption, especially for watt tape installations.

- Mechanical Stress: Minimize repeated flexing or sharp bending at the heater to avoid damage.

Durability, Safety, And Materials

- Film Construction: Polyimide films offer high heat resistance and dielectric strength suitable for electronics and tooling tasks.

- Safety Features: Use controllers with over-temperature protection and appropriate fusing for the supply circuit.

- Environmental Factors: Consider moisture, chemical exposure, and UV if the heater is installed outdoors or in harsh conditions.

Application-Specific Considerations

- Electronics/3D Printing: Prefer thin polyimide film heaters for conformal mounting on beds or housings; use a closed-loop controller and sensor for stable temperatures.

- Pipes And Tubing: Opt for wider flex watt tape wrapped with thermal insulation for uniform temperature along the length.

- Sign Making And Bending: Integrated bender units or strip heaters designed for forming deliver precise linear heat; cooling systems help control heat-affected zones.

Comparative Perspectives

- Thin Film Heaters (Coliao, DWEII 24V & 12V): Best for compact, low-profile applications requiring precise localized heating. They require external control but offer excellent thermal contact when adhered properly.

- Heat Tape / Watt Tape (Flexwatt): Better for broader coverage and wraparound heating. Less discreet but often simpler for elongated components.

- Built Tools (Portable Bender): Suited for process heating and forming rather than continuous surface heating. These units combine heaters with mechanical fixtures and cooling for repeatable bends.

Installation Checklist

- Confirm voltage and power supply capacity.

- Plan for temperature control and sensor placement close to the target surface.

- Prepare the mounting surface: clean, dry, and flat where possible.

- Secure heater with recommended adhesive or mechanical fastening; avoid sharp bends.

- Insulate as needed to improve efficiency and protect surroundings.

- Test system with monitoring for stable operation before leaving unattended.

Final Selection Tips

- Match the heater’s geometry to the heating zone to reduce the need for multiple elements.

- When in doubt about control, choose a heater with lower power density and add a controller capable of PID tuning for steady performance.

- Consider spare elements or modular designs if long runs or redundancy is important.