Polyimide film heaters (PI heaters) are thin, flexible heating elements used for 3D printer beds, tooling, electronics warm-up, and localized heat applications. This guide compares five widely available polyimide heaters and related high-temperature polyimide tapes to help you choose the right solution for your application.

| Product | Key Specs | Use Case |

|---|---|---|

| Coliao 24V 30W Film Heater Plate | 24V, 30W, ~170°C max | 3D printer bed, small plate heating |

| Harissess 12V 25W Film Heater Plate | 12V, 25W, ~170°C max, 100x100mm | Smaller beds, low-voltage systems |

| DWEII 24V 30W Film Heater Pack | 24V, 30W, ~170°C max (10 pcs) | Bulk replacement heaters, OEM repairs |

| Tgoon Flexible PI Heater Plate 24V 150W | 24V, 150W, 150°C rating, 100K thermistor | Larger 3D printer beds needing faster heat |

| JUZITAO 5V 1W Small PI Heater Strips | 5V, 1W, 30x40mm, ~150°C max | Localized heating in electronics, instruments |

Content Navigation

- Coliao 24V 30W Film Heater Plate Adhesive Pad

- Harissess 12V 25W Film Heater Plate Adhesive Pad

- DWEII 24V 30W Film Heater Plate Adhesive Pads (10 Pack)

- Tgoon Flexible Polyimide Heater Plate With 100K Thermistor

- JUZITAO 5V 1W Small PI Heater Strip (10 Pack)

- Related Polyimide Tape Options

- Buying Guide: How To Choose A Polyimide Film Heater

- Voltage And Power Requirements

- Maximum Temperature And Thermal Rating

- Size, Shape, And Flexibility

- Adhesive Backing And Mounting Method

- Temperature Sensing And Control

- Safety And Insulation

- Power Distribution And Wiring

- Application-Specific Considerations

- Longevity And Environmental Factors

- Comparison Perspectives

Coliao 24V 30W Film Heater Plate Adhesive Pad

This polyimide heater film is specified for DC 24V and 30W output with a listed maximum temperature around 170°C. It uses a thin thermo-foil heating element sealed within polyimide insulation.

- Fast Preheating: The thermo-foil core provides quick heat-up once powered.

- Stable Operation: The film maintains steady temperature when paired with external control.

- Safety &insulation: Polyimide offers high heat resistance and insulation strength.

- Control Requirement: The heater does not include built-in temperature control — use a compatible 24V temperature controller or thermostat.

Best suited for retrofitting or replacing a small 3D printer bed or for lightweight surface heating where 24V systems are standard.

Harissess 12V 25W Film Heater Plate Adhesive Pad

The Harissess film heater is a flexible adhesive heater at 12V and 25W, often supplied as a 100mm x 100mm pad. It combines polyimide outer layers with internal foil and wire heating elements.

Call 888-896-7031 for Free Local HVAC Quotes – Compare and Save Today!

- Flexibility: Soft and conformable for curved or flat mounting.

- Electrical Insulation: Polyimide keeps dielectric properties stable across temperatures.

- Temperature Range: Maximum temp approximately 170°C; requires external controller for temperature regulation.

- Application: Fits low-voltage 3D printer beds, heat-mapping fixtures, or localized component warming.

The adhesive backing simplifies mounting to metal or composite plates; check adhesive compatibility for long-term adhesion on your substrate.

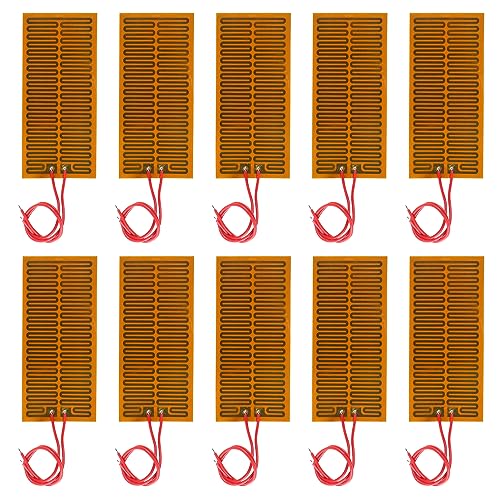

DWEII 24V 30W Film Heater Plate Adhesive Pads (10 Pack)

This DWEII offering provides multiple 24V, 30W polyimide heaters in a bulk pack for projects, repairs, or production use.

- Bulk Supply: Multiple identical heaters useful for spares or multi-station setups.

- Thermal Characteristics: Typical maximum temperature near 170°C and good thermal conductivity.

- Dielectric Strength: Polyimide construction offers excellent insulation and stability.

- Control Needs: Requires an external 24V temperature controller for safe, repeatable temperatures.

Choose this pack if you need several replacement heaters or want an inventory for repeated installations. Verify size fit and adhesive strength for your intended mounting surface.

Tgoon Flexible Polyimide Heater Plate With 100K Thermistor

The Tgoon flexible PI heater is designed for faster heating and includes a built-in 100K thermistor for temperature sensing. Listed as DC24V and 150W with a 150°C rating, it targets larger beds and faster warm-up needs.

Call 888-896-7031 for Free Local HVAC Quotes – Compare and Save Today!

- High Power Output: 150W delivers faster heat-up over larger areas compared with lower-wattage pads.

- Integrated Sensor: The included 100K thermistor allows direct temperature feedback to compatible controllers.

- Polyimide Benefits: Provides good dielectric strength, heat transfer efficiency, and flexible mounting.

- Intended Uses: Larger 3D printer beds or applications where rapid, even heating is required.

Because of the higher wattage, confirm your power supply and controller compatibility. The included thermistor simplifies integration with common 3D printer controllers that support external bed sensors.

JUZITAO 5V 1W Small PI Heater Strip (10 Pack)

These compact polyimide heater strips operate at DC 5V and ~1W power, sized at approximately 30mm x 40mm. They are ultra-thin and intended for localized heating in instruments or electronics.

- Low-Voltage Use: Designed for 5V systems and small-surface heating tasks.

- Ultra-Thin Flexibility: Less than 0.4mm thick for tight spaces or curved surfaces.

- Safe Insulation: Polyimide film provides stable dielectric performance over varied temperatures.

- Temperature Control: Max temperature around 150°C; use with a low-voltage controller for regulation.

These are appropriate for sensor warming, condensation prevention, or small component heating where low power and compact size are required.

Related Polyimide Tape Options

High-temperature polyimide adhesive tapes are commonly used to secure PI film heaters, mask components, or protect PCBs during rework. Two representative tape options from the product list:

- CoYlBod 1″ Polyimide Tape: Rated to 260°C, silicone adhesive leaves no residue and suits heat presses, soldering, and 3D printing tasks.

- MS WGO 13mm x 100ft Tape: High-temp tape that withstands over 450°F and resists brittleness after heating.

Use such tapes for temporary adhesion, edge sealing, or masking when mounting film heaters—verify adhesive compatibility and long-term exposure limits.

Buying Guide: How To Choose A Polyimide Film Heater

Selecting the right polyimide film heater requires balancing power, size, control, mounting, and safety. Below are the essential factors to evaluate before purchase.

Voltage And Power Requirements

Match the heater voltage to your system (5V, 12V, 24V, etc.). Higher wattage produces faster heat and higher steady-state energy use. Ensure your power supply can deliver the required voltage and current continuously.

Maximum Temperature And Thermal Rating

Check the listed maximum temperature (often 150–170°C for many PI heaters). Choose a heater rated above the temperature you need for safe operation, and remember polyimide film itself tolerates high temperatures while adhesives or substrates may limit usable range.

Size, Shape, And Flexibility

Confirm physical dimensions match the target surface. Flexible sheets adapt to curved or irregular surfaces; rigid plates require flat mounting. Ultra-thin heaters are best for tight spaces.

Adhesive Backing And Mounting Method

Some heaters include adhesive backing; others require separate adhesive tape or mechanical clamping. Use high-temperature polyimide tape for temporary bond or to protect heater edges. Verify long-term adhesive performance on your substrate material.

Temperature Sensing And Control

Many heaters require an external temperature controller; some include a built-in thermistor. For repeatable, safe operation use a controller with PID tuning or a relay/SSR setup and a properly rated sensor placed near the heater surface.

Safety And Insulation

Polyimide provides excellent dielectric strength, but you must ensure electrical connections are insulated and strain-relieved. Consider fuses, thermal cutoffs, or redundant temperature monitoring in critical applications.

Power Distribution And Wiring

Check lead thickness and connector type. Higher currents need thicker wires and secure crimping or solder joints to avoid heating at connections. For multi-pad systems, balance power distribution and ensure even heat.

Application-Specific Considerations

- 3D Printing: Prefer heaters with an integrated thermistor or accessible sensor location, and wattage appropriate to bed size.

- Electronics/Instrument Heating: Low-power, small-size pads or strips are preferable for localized warming and sensor protection.

- Production/OEM: Bulk packs and consistent size tolerances may be important; verify supplier quality control.

Longevity And Environmental Factors

Account for cycle life, exposure to moisture, chemicals, or mechanical abrasion. Choose adhesive and polyimide thickness appropriate for repeated thermal cycles if used continuously.

Comparison Perspectives

- Performance vs. Power: Higher wattage heats faster but increases power needs and thermal stress.

- Cost vs. Quantity: Bulk packs reduce per-unit cost but require inventory and fit verification.

- Integration vs. Simplicity: Heaters with integrated thermistors simplify control wiring; standalone films offer flexibility for custom sensor placement.

- Mounting vs. Serviceability: Permanent adhesive gives neat installation but complicates replacements; removable tape allows easier maintenance.

When selecting a polyimide film heater, cross-check the heater’s electrical rating, physical fit, and control strategy with your system’s power delivery and safety measures to ensure reliable operation.

Tips for Getting the Best HVAC Prices

- Prioritize Quality Over Cost

The most critical factor in any HVAC project is the quality of the installation. Don’t compromise on contractor expertise just to save money. - Check for Rebates

Always research current rebates and incentives — they can significantly reduce your overall cost. - Compare Multiple Quotes

Request at least three estimates before making your choice. You can click here to get three free quotes from local professionals. These quotes include available rebates and tax credits and automatically exclude unqualified contractors. - Negotiate Smartly

Once you've chosen a contractor, use the proven strategies from our guide — How Homeowners Can Negotiate with HVAC Dealers — to get the best possible final price.