Polyimide (PI) heater elements deliver thin, flexible heat for electronics, 3D printers, lab equipment, and industrial applications. This guide compares five widely used PI and PTC heater plates tailored for different voltages, sizes, and power ratings to help you match heater performance to your application.

| Product | Voltage / Power | Size / Key Feature |

|---|---|---|

| Coliao 45×100 Film Heater | 24V / 30W | Polyimide film, max ~170°C |

| DWEII 45×100 Film Heater (10 pcs) | 24V / 30W | Dielectric strength, thermal stability |

| PTCYIDU PTC Aluminum Shell Heater | AC/DC 12V options, 5–50W range | PTC ceramic, aluminum shell, constant temp |

| Harissess 100×100 Film Heater | 12V / 25W | Flexible PI, larger 100mm×100mm pad |

| XIITIA 25×50 Film Heater (15 pcs) | 12V / 7W | Small, lightweight, flexible |

Content Navigation

Coliao 45mmx100mm Film Heater Plate

Voltage And Power: DC 24V, 30W. Temperature Capability: Maximum about 170°C. The product uses polyimide as the outer insulator with thermo foil as the internal heating element.

Performance Notes: The heater provides fast preheating and then maintains stable temperatures once the interior reaches operating range. It does not include internal temperature control; an external 24V temperature controller is recommended for closed-loop control.

Durability And Safety: Polyimide film offers excellent heat resistance, high insulation strength, and resistance stability. Long service life and stable performance are cited, suitable for adhesive mounting where thin form factor matters.

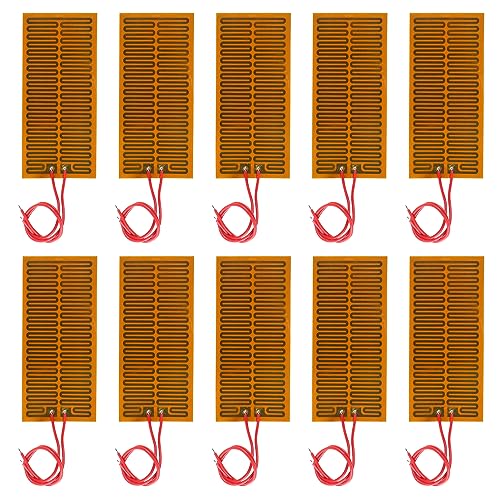

DWEII 45mmx100mm Film Heater Pad

Call 888-896-7031 for Free Local HVAC Quotes – Compare and Save Today!

Voltage And Power: DC 24V, 30W. Temperature Capability: Maximum around 170°C. The heater shares similar basic specifications with other 24V PI pads but is offered as a multi-pack option.

Electrical And Thermal Properties: Highlights include excellent dielectric strength, thermal conductivity efficiency, and resistance stability. As with most PI films, temperature regulation requires an external controller for precise control.

Typical Uses: Recommended for use where consistent surface heating is needed on small assemblies, sensor mounts, or tooling fixtures. The form factor supports adhesive installation and fast warm-up cycles.

PTCYIDU PTC Aluminum Shell Heater

Construction: Uses a PTC ceramic heating element enclosed in an aluminum shell. Lead wires are high-temperature rated for durability and straightforward installation.

Temperature Behavior: PTC heaters offer self-regulating characteristics — as temperature rises, resistance increases, which limits current and stabilizes temperature. The listing notes constant-temperature thermostatic operation suitable for dry heating.

Call 888-896-7031 for Free Local HVAC Quotes – Compare and Save Today!

Applications And Safety: The aluminum shell aids heat transfer and mounting. Suitable for applications that require a stable setpoint without continuous active control, and where mechanical robustness is advantageous compared to ultra-thin PI films.

Harissess 100mmx100mm Film Heater Pad

Voltage And Power: DC 12V, 25W. Size: 100mm × 100mm, larger surface area compared to narrow strips.

Material And Performance: Constructed with polyimide outer film, metal foil conductive element, and heat-sealed edges. The design emphasizes flexibility, fast preheating, and stable resistance under repeated cycles.

Use Cases: The larger pad size suits applications requiring distributed heating such as heated beds for small devices, component warmers, or localized de-icing. As with other films, temperature control requires an external controller for precise regulation.

XIITIA 25mmx50mm Film Heater Pack

Voltage And Power: DC 12V, 7W. Characteristics: Lightweight, flexible, and small footprint suitable for tight spaces or many-point heating schemes.

Performance Notes: The film provides stable surface temperature once warmed and is designed for quick response. The seller emphasizes typical PI strengths: good dielectric strength, efficient heat transfer, and wide application in electronics and instruments.

Installation: Small size and self-adhesive options (where supplied) make these pads easy to apply to curves, housings, or internal PCB areas where localized heat is required.

Buying Guide For Polyimide Heater Elements

When choosing a polyimide or PTC heater element, evaluate technical compatibility, installation requirements, and long-term performance. The following factors provide a multi-perspective checklist to ensure you select the right heater for your project.

Tips for Getting the Best HVAC Prices

- Prioritize Quality Over Cost

The most critical factor in any HVAC project is the quality of the installation. Don’t compromise on contractor expertise just to save money. - Check for Rebates

Always research current rebates and incentives — they can significantly reduce your overall cost. - Compare Multiple Quotes

Request at least three estimates before making your choice. You can click here to get three free quotes from local professionals. These quotes include available rebates and tax credits and automatically exclude unqualified contractors. - Negotiate Smartly

Once you've chosen a contractor, use the proven strategies from our guide — How Homeowners Can Negotiate with HVAC Dealers — to get the best possible final price.

Voltage And Power Matching

- Confirm system voltage compatibility (5V, 12V, 24V, AC options). Mismatched voltage reduces heating or risks damage.

- Choose power (watts) based on required temperature rise, pad area, and thermal losses — higher W for faster heating or larger areas.

Temperature Range And Control

- Check the maximum rated temperature (PI films often up to ~170°C; smaller/low-voltage pads may be ~100–150°C).

- PI heaters are typically open-loop — use an external temperature controller or thermostat and a thermistor/thermocouple for closed-loop regulation.

- Consider PTC heaters if self-regulating behavior is desirable to limit peak temperatures without active control.

Form Factor And Mounting

- Select pad dimensions that match the contact area. Larger pads distribute heat; narrow strips concentrate heat.

- Adhesive-backed films simplify mounting but confirm adhesive temperature rating and surface compatibility.

- Rigid or enclosed heaters (aluminum-shell PTC units) offer mechanical robustness and easier screw/clip mounting.

Thermal Management And Heat Transfer

- Evaluate thermal conductivity of the target surface: metals transfer heat more effectively than plastics.

- Use thermal interface materials if high conduction to the workpiece is required.

- Account for airflow and convective losses — enclosed spaces retain heat better than open-air applications.

Electrical And Safety Considerations

- Verify dielectric strength and insulation ratings for electrically sensitive assemblies.

- Ensure lead wires and connectors are rated for the operating temperature and are strain-relieved.

- Overcurrent protection (fuses or breakers) and thermal cutoffs add safety in fault conditions.

Durability, Cycling, And Environmental Factors

- Polyimide films tolerate wide temperature ranges and repeated cycles, but check manufacturer longevity data for continuous operation.

- Consider moisture, chemicals, and abrasion exposure; sealed or encapsulated heaters fare better in harsh environments.

- For vibration or mechanical wear, choose units with protective shells or mounting hardware.

Application-Specific Selection

- Electronics / PCB warming: small flexible PI pads (low wattage) for localized heat.

- Heated plates / small beds: larger area PI pads or multiple small pads in an array for even distribution.

- Temperature-critical instrumentation: combine PI or PTC heaters with accurate sensors and controllers for closed-loop stability.

Cost, Sourcing, And Multipacks

- Multipacks are useful for prototyping or arrays; verify quality consistency across pieces.

- Check supplier documentation for electrical schematics, recommended controllers, and safety certifications.

Installation And Testing Tips

- Run initial tests with a current-limited power supply and thermal probe to validate warm-up time and steady-state temperature.

- Secure wiring and add slack loops to prevent stress on solder joints or pads during thermal cycling.

- Document placement and wiring for repeatable replacement or scaling of the design.