Choosing the right round duct heater and matching round duct components affects system efficiency, safety, and installation ease. The table below highlights the selected products in this guide to help you compare core features quickly.

| Product | Primary Use | Key Feature |

|---|---|---|

| Warren SL5A 5 KW Electric Duct Heater | In-duct heating element | 5000W, 24V control |

| Vent Systems 6″ White Plastic Adjustable Diffuser | Air distribution / register | Adjustable valve, foam insulation |

| HVAC OV 6″ To 4″ Round Duct Reducer | Size transition | Male fit, raised lip for clamps |

| Vent Systems 5″ Galvanized Steel Duct Connector | Duct coupling | Galvanized steel, male fit |

| Achtek 6″ Solid Cast Aluminum Round Grille | Floor or wall grille | Powder coated, solid faceplate |

Content Navigation

- Warren SL5A 5 KW Electric Duct Heater

- Vent Systems 6″ White Plastic Adjustable Diffuser

- HVAC OV 6″ To 4″ Round Duct Reducer

- Vent Systems 5″ Galvanized Steel Duct Connector

- Achtek 6″ Solid Cast Aluminum Round Grille

- Buying Guide: Choosing Round Duct Heaters And Components

- 1. Match Heater Capacity To Duct And Space

- 2. Electrical And Control Requirements

- 3. Duct Size Compatibility And Transitions

- 4. Airflow Restriction And Pressure Drop

- 5. Material Selection And Durability

- 6. Noise, Vibration, And Insulation

- 7. Installation And Mounting Considerations

- 8. Safety And Code Compliance

- 9. Air Distribution And Zoning

- 10. Maintenance And Accessibility

- Comparison Perspectives

Warren SL5A 5 KW Electric Duct Heater

The Warren SL5A is an in-duct electric heater designed for HVAC integration. It delivers 5000W of heat and is configured for 240V single-phase service with 24V control for on/off operation. Its in-duct form factor allows installation directly into round duct sections or plenum spaces where an inline heating element is required.

Key features listed include powerful heating output, an efficient in-duct design for seamless HVAC integration, and 24V control compatibility for standard thermostat or control interfaces. For safe operation, confirm duct diameter, available branch space, and required electrical service before installation. Appropriate overcurrent protection and adherence to local electrical and mechanical codes are essential.

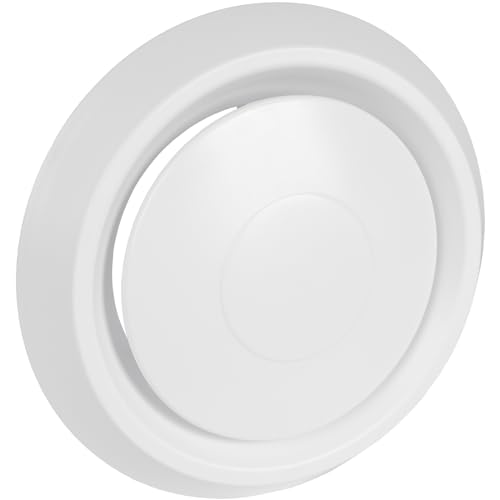

Vent Systems 6″ White Plastic Adjustable Diffuser

This white plastic 6-inch adjustable diffuser functions as a register or vent cover for round duct outlets. The listing highlights precise flange dimensions with a 5.87″ inner diameter and an 8.46″ outer diameter, and a collar length of about 2.91″. The rotating valve enables airflow adjustment for room-level balancing.

Call 888-896-7031 for Free Local HVAC Quotes – Compare and Save Today!

Other features include foam insulation beneath the cover to help reduce noise and vibration and dual-purpose operation for distributing conditioned air and facilitating exhaust when configured. Screws and hardware are not included, so plan mounting fasteners and verify compatibility with the duct collar or grille opening you intend to use.

HVAC OV 6″ To 4″ Round Duct Reducer

This galvanized steel duct reducer converts between round sizes, with the smallest opening approximately Ø3.81″ and the largest about Ø5.78″. Both openings are male fit and feature a raised lip to improve grip for clamps and fasteners. The part is intended for joining solid or flexible round ducts when a size transition is required.

The product emphasizes robust, solid construction and recommends securing the reducer with clamps or preferred fasteners after installation. Use this type of reducer when integrating a heater element, grille, or register where the duct diameter differs from the component inlet to ensure a proper mechanical and airflow connection.

Vent Systems 5″ Galvanized Steel Duct Connector

The Vent Systems 5-inch galvanized coupler is a two-hole male fit connector made from galvanized steel. Its outside diameter is roughly 4.9 inches and it is designed for straightforward coupling of round duct sections. The listing notes quality galvanized material for strength and durability.

Call 888-896-7031 for Free Local HVAC Quotes – Compare and Save Today!

Installation is described as easy when paired with compatible 5-inch pipes, vents, or connectors. The recommendation to secure pipe ends with steel clamps aligns with typical ductwork practice, particularly important when joining ducts around inline heaters to ensure robust mechanical joins and proper airflow sealing.

Achtek 6″ Solid Cast Aluminum Round Grille

The Achtek 6-inch solid cast aluminum grille is offered as a powder-coated black finish with no perforations, suitable for floor or wall installations where a solid face is desired. The grille fits a standard duct opening diameter of 6 inches and has an overall faceplate size of 7-1/2 inches, with a protrusion/lip of 1-7/16 inches.

Solid face grilles can be used for protected terminations or where a clean aesthetic is prioritized. When used with duct heaters, verify that the grille allows adequate airflow for the heater’s output and does not create undue restriction that affects pressure drop or heating performance.

Buying Guide: Choosing Round Duct Heaters And Components

This buying guide covers critical considerations across performance, compatibility, safety, and installation to help match a round duct heater with supporting components like diffusers, reducers, connectors, and grilles.

1. Match Heater Capacity To Duct And Space

Select a heater wattage aligned with the airflow (CFM) and the target temperature rise. A heater like the Warren SL5A lists 5000W output; check system airflow and required delta-T to confirm the heater will meet space heating needs without excessive duct temperatures.

2. Electrical And Control Requirements

Confirm voltage, phase, and control interface. The Warren heater uses 240V single-phase with 24V control, which integrates with many thermostats. Ensure your electrical service, breaker sizing, and wiring comply with local codes and manufacturer instructions.

3. Duct Size Compatibility And Transitions

Use reducers or couplers to adapt between component diameters. The HVAC OV reducer and Vent Systems coupler provide male fit transitions. Measure inner diameters precisely and account for collar lengths and raised lips when planning connections.

4. Airflow Restriction And Pressure Drop

Grilles and diffusers introduce pressure drop. Adjustable diffusers like the Vent Systems 6″ model enable balancing but can increase resistance at partial closure. Solid face grilles reduce leakage but may increase backpressure; ensure the heater’s performance is not compromised by restricted flow.

5. Material Selection And Durability

Galvanized steel connectors offer robustness in HVAC runs; plastic diffusers are lightweight and corrosion-resistant. Aluminum grilles provide longevity and a finished look. Choose materials appropriate for the environment (e.g., indoor, moist, or exposed locations).

6. Noise, Vibration, And Insulation

Foam-insulated diffusers help reduce noise and vibration transmission. In-duct heaters can create airflow noise at higher velocities; consider diffuser design and acoustic insulation where low sound levels are important.

7. Installation And Mounting Considerations

Confirm collar lengths, flange diameters, and lip protrusion to ensure components align in the duct run. Many small parts ship without mounting hardware; plan for clamps, screws, or specialized brackets. Secure mechanical joints especially around heaters for safety.

8. Safety And Code Compliance

Follow local electrical and mechanical codes. Heaters require appropriate overcurrent protection, temperature limits, and clearances. Use compatible thermostats and controls with proper wiring. Verify manufacturer guidelines on minimum airflow and mounting orientation.

9. Air Distribution And Zoning

Diffusers with adjustable valves support room-level balancing. When a heater serves multiple zones, ensure controls and dampers are configured to prevent overheating or reverse airflow. Consider motorized dampers for automated zoning control.

10. Maintenance And Accessibility

Plan for access to the heater element, controls, and connectors for cleaning and servicing. Components that are easily removable or located in a serviceable section of the ductwork reduce downtime and improve long-term performance.

Comparison Perspectives

- Performance-Centric: Prioritize heater wattage and airflow matching; then choose low-resistance diffusers.

- Installation-Centric: Focus on collar dimensions, raised lips and clamp compatibility to simplify assembly.

- Durability-Centric: Select galvanized steel or cast aluminum for long-life duct runs; plastic diffusers for moisture resistance where appropriate.

- Acoustics-Centric: Use foam-insulated diffusers and avoid abrupt transitions that create turbulence and noise.

- Safety-Centric: Verify electrical configuration, protective devices, and minimum airflow requirements for in-duct heaters.

Use the combination of a correctly sized heater, properly matched connectors and grille, and appropriate controls to achieve safe, efficient, and quiet round duct heating. Carefully measure duct dimensions and verify listed features against your system requirements before purchase and installation.

Tips for Getting the Best HVAC Prices

- Prioritize Quality Over Cost

The most critical factor in any HVAC project is the quality of the installation. Don’t compromise on contractor expertise just to save money. - Check for Rebates

Always research current rebates and incentives — they can significantly reduce your overall cost. - Compare Multiple Quotes

Request at least three estimates before making your choice. You can click here to get three free quotes from local professionals. These quotes include available rebates and tax credits and automatically exclude unqualified contractors. - Negotiate Smartly

Once you've chosen a contractor, use the proven strategies from our guide — How Homeowners Can Negotiate with HVAC Dealers — to get the best possible final price.