Working in cold weather requires reliable heating solutions for both the operator cab and engine components of skid steer loaders. This guide compares five relevant skid steer heater kit and related components, highlighting fitment, features, and use cases to help you choose the right kit or replacement part for your machine.

| Product | Brand | Key Feature |

|---|---|---|

| Heater & Cabin Air Filter Kit Fit for Bobcat Skid Steer Loader A220 A300 … | Fitede | Cabin Air Filter Replacement Compatible With Many Bobcat Models |

| KV12758HT Bolt On Skid Steer Heat Treated Cutting Edge with Hardware | Digger Supply | Heat Treated Steel Cutting Edge — durability for loader work |

| Engine Heater Kit for GEHL Loaders SL5620 Skid Steer w/Perkins 4.154 Eng. | HFM | 400 Watt Engine Block/Immersion Heater — Made In USA |

| Saihisday Cab Heater Air Filter 6678207 Replacement for Bobcat Skid Steer | Saihisday | Cab Heater Air Filter Replacement; Easy Installation |

| RAParts KV20850 New Heater Core Fits John Deere 240 250 260 270 Skid Steer | Reliable Aftermarket Parts | Aftermarket Heater Core Specific Fit For Several John Deere Models |

Content Navigation

- Heater & Cabin Air Filter Kit Fit For Bobcat Skid Steer Loader A220 A300

- KV12758HT Bolt On Skid Steer Heat Treated Cutting Edge With Hardware

- Engine Heater Kit For GEHL Loaders SL5620 Skid Steer With Perkins Engine

- Saihisday Cab Heater Air Filter 6678207 Replacement For Bobcat Skid Steer

- RAParts KV20850 New Heater Core Fits John Deere 240 250 260 270 Skid Steer

- Buying Guide For Skid Steer Heater Kits And Components

- 1. Determine What You Need: Cab Heater Component vs Engine Heater

- 2. Verify Fitment And OEM Part Numbers

- 3. Heater Type And Wattage

- 4. Material Quality And Construction

- 5. Installation Complexity

- 6. Electrical Supply And Safety

- 7. Operating Environment And Duty Cycle

- 8. Related Maintenance Items To Consider

- 9. Compatibility With Attachments And Cutting Edges

- 10. Aftermarket Versus OEM Considerations

- 11. Troubleshooting Common Heater Problems

- 12. Comparison Perspectives

- 13. Installation And Service Documentation

- 14. Warranty And Return Policies

- 15. Final Selection Checklist

Heater & Cabin Air Filter Kit Fit For Bobcat Skid Steer Loader A220 A300

This product is a cab heater air filter replacement designed to filter dust, debris, soot, and dirt from the operator compartment air. It lists compatibility with a wide range of Bobcat models including A220, A300, multiple track loader and skid steer series, and specific OE reference numbers.

- Function: Cabin air filtration to improve in-cab air quality and dust prevention.

- Replaces: Part numbers 6677983, 6678207, 6677983-A, and equivalent OE cross-references.

- Compatibility: Extensive list covering Bobcat all-wheel steer, track loader, and skid steer lines.

This item focuses on the air filtration aspect of the cab heater system rather than providing a heating element. It is appropriate when cab airflow or cabin heater performance is affected by a clogged or degraded filter. Verify OEM part numbers against your machine before ordering to confirm fitment.

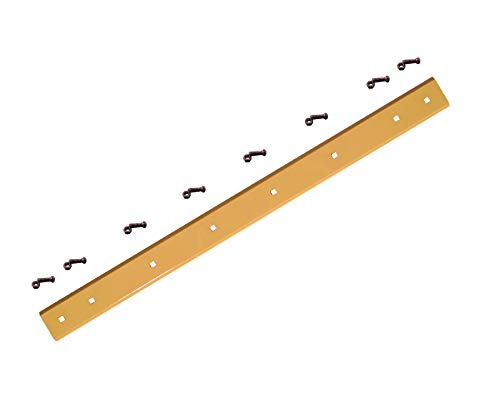

KV12758HT Bolt On Skid Steer Heat Treated Cutting Edge With Hardware

Although not a heater kit, this heat-treated cutting edge is included because winter operations often require ensuring the machine’s attachments are ready for frozen ground and abrasive conditions. The product is compatible with various John Deere skid steer models.

Call 888-896-7031 for Free Local HVAC Quotes – Compare and Save Today!

- Model Fit: Designed to fit specified John Deere models, listed as KV12758.

- Material: Heat-treated steel for improved wear resistance.

- Hardware: Bolt-on with included installation hardware for retrofit.

Replacing or upgrading cutting edges can affect machine performance in winter, improving traction and material penetration so the engine and heater work under standard load. This entry helps readers consider related maintenance tasks that support effective cold-weather operation.

Engine Heater Kit For GEHL Loaders SL5620 Skid Steer With Perkins Engine

This engine heater kit offers a 400-watt heating element intended for pre-warming engine coolant or an engine block on compatible GEHL skid steer models with Perkins engines. It is identified by a 30mm diameter and is manufactured in the USA.

- Power: 400 Watts — intended for coolant or block pre-heating to aid cold starts.

- Fitment: Specified for GEHL SL5620 with Perkins 4.154 engines; verify fit for other models.

- Origin: Made in USA, which may be relevant for sourcing or quality considerations.

An engine heater of this type reduces cold-start wear, shortens warm-up time, and improves fluid flow during startup. Ensure electrical supply compatibility and mounting fits are verified before installation, and follow the manufacturer’s instructions for safe wiring and use.

Saihisday Cab Heater Air Filter 6678207 Replacement For Bobcat Skid Steer

This listing provides a replacement cab heater air filter specified as compatible with Bobcat part number 6678207. It targets a range of Bobcat skid steer and track loader models and notes easy installation and stable performance characteristics.

Call 888-896-7031 for Free Local HVAC Quotes – Compare and Save Today!

- Replace Part Number: Compatible with OEM 6678207.

- Fitment Range: Multiple Bobcat skid steer and track loader models listed for compatibility.

- Performance: Described as reliable with potential benefits for fuel efficiency and engine reliability through cleaner intake air.

As with other filter replacements, confirm the OEM part number and physical dimensions before purchase. Replacing cabin air filters can be a straightforward maintenance task that supports HVAC system performance and operator comfort.

RAParts KV20850 New Heater Core Fits John Deere 240 250 260 270 Skid Steer

This product is an aftermarket heater core intended to replace the in-cab heater core for specified John Deere skid steer models. Heater cores are central to cabin heat delivery by circulating engine coolant through a compact radiator to warm air blown into the cab.

- Fitment: Listed for John Deere models 240, 250, 260, 270 — verify compatibility before ordering.

- Type: Aftermarket heater core — intended as a direct replacement component.

- Note: Product images may be generic; confirm part details prior to installation.

Replacing a failed heater core restores cab heat and defrost functionality. When selecting a replacement, check inlet/outlet locations, hose sizes, and mounting points to ensure a correct fit. Consider coolant system inspection during heater core replacement to address related issues like leaks or corrosion.

Buying Guide For Skid Steer Heater Kits And Components

This buying guide outlines the key considerations when selecting heater kits, heater cores, engine heaters, and related cabin components for skid steers. Use the sections below to compare options and ensure compatibility with your equipment and operating needs.

1. Determine What You Need: Cab Heater Component vs Engine Heater

Identify whether you need a cab heat system part (heater core, blower motor, cabin air filter) or an engine/coolant heater (immersion heater, block heater). Cabin issues typically cause low heat output, fogging, or poor air quality. Engine heater needs are driven by cold starts and fluid viscosity concerns.

2. Verify Fitment And OEM Part Numbers

Always cross-check OEM part numbers and machine model years. Many replacement listings include OEM references (e.g., 6678207, 6677983). Matching part numbers avoids returns and ensures correct hose and mounting alignment.

3. Heater Type And Wattage

For engine pre-heaters, consider wattage and intended application. A 400-watt immersion or inline heater provides modest pre-warming ideal for moderate climates; higher wattage units warm faster but require adequate electrical supply. Confirm voltage and plug type compatibility with your site power.

4. Material Quality And Construction

Heater cores should be constructed with corrosion-resistant materials, appropriate brazing, and correct fin design for efficient heat transfer. Engine heaters and elements benefit from robust housings and seals to withstand coolant exposure and vibration.

5. Installation Complexity

Cab heater core or filter replacements are often moderate DIY tasks if you have basic tools and access to the cab and firewall areas. Engine heaters may need coolant draining, wiring to power, and secure mounting. If unsure, plan for professional installation to ensure safe electrical connections and leak-free coolant routing.

6. Electrical Supply And Safety

Confirm the available power source on-site (120V, 240V, etc.). Block or coolant heaters require proper circuit protection, outdoor-rated plugs, and grommets if wiring through bulkheads. Use GFCI protection where required and follow local electrical codes for mobile equipment.

7. Operating Environment And Duty Cycle

Estimate how long heaters will be used daily and under what temperatures. Frequent overnight use suggests investing in a reliable block heater and robust cab heating components. For intermittent or mild cold, replacing cabin filters and ensuring the heater core is functional may suffice.

8. Related Maintenance Items To Consider

- Cabin Air Filters: Replace clogged filters to restore airflow and prevent dust from reducing heater effectiveness.

- Coolant Condition: Test coolant freeze protection and change if contaminated; heater performance depends on clean, effective coolant.

- Hoses And Clamps: Inspect for cracking and replace to prevent leaks when replacing cores or installing heaters.

- Blower Motor And Controls: Verify blower operation and control functionality as heat requires proper air movement.

9. Compatibility With Attachments And Cutting Edges

Winter tasks often require robust attachments like heat-treated cutting edges. While not a heater component, maintaining cutting edges and attachment hardware ensures efficient operation and reduces overload on the engine and heating system during heavy-duty cold-weather work.

10. Aftermarket Versus OEM Considerations

Aftermarket parts may offer cost or availability advantages but check warranty, material specifications, and return policies. OEM parts provide direct fit and original specifications but may have longer lead times. Assess installation complexity and long-term durability expectations when choosing between aftermarket and OEM replacements.

11. Troubleshooting Common Heater Problems

- Weak Cab Heat: Check cabin air filter, blower motor, thermostat operation, heater core blockage, and coolant level.

- No Heat At Startup: Confirm coolant temperature and engine warm-up, check thermostat, and inspect heater core for leaks or clogging.

- Electrical Issues With Engine Heater: Verify power supply, cord integrity, plug and GFCI function, and internal element continuity.

- Fogging Or Odor: Inspect for coolant leaks into the cab (heater core leak) and replace the heater core if necessary.

12. Comparison Perspectives

Compare products by function: cabin air filters (Fitede, Saihisday) focus on airflow and air quality, heater cores (RAParts) address core heat delivery to the cab, and engine heaters (HFM) provide pre-heating for starting efficiency. Also consider related maintenance items like cutting edges (Digger Supply) that influence overall winter performance.

13. Installation And Service Documentation

Locate service manuals or OEM diagrams that show heater core location, hose routing, and electrical connections. Accurate diagrams reduce installation time and prevent incorrect routing that could cause leaks or electrical hazards.

14. Warranty And Return Policies

Review seller warranties and return policies on replacement parts. Aftermarket suppliers may offer different terms than OEM dealers. Retain proof of purchase and document part numbers and photos during installation to support warranty claims if issues arise.

Tips for Getting the Best HVAC Prices

- Prioritize Quality Over Cost

The most critical factor in any HVAC project is the quality of the installation. Don’t compromise on contractor expertise just to save money. - Check for Rebates

Always research current rebates and incentives — they can significantly reduce your overall cost. - Compare Multiple Quotes

Request at least three estimates before making your choice. You can click here to get three free quotes from local professionals. These quotes include available rebates and tax credits and automatically exclude unqualified contractors. - Negotiate Smartly

Once you've chosen a contractor, use the proven strategies from our guide — How Homeowners Can Negotiate with HVAC Dealers — to get the best possible final price.

15. Final Selection Checklist

- Confirm machine make/model and OEM part number.

- Decide whether cab heater component, heater core, or engine heater is required.

- Verify electrical supply and mounting space for engine heaters.

- Inspect related systems (coolant, hoses, blower motor) before replacing parts.

- Choose OEM vs aftermarket based on fitment certainty and warranty needs.